1. Specialist actuator manufacturer with unwavering focus on serving valve OEMs and end users.

2. Widest range of torque selections available, from 5 N-m to 7,800 N-m (44 lb-in to 69,000 lb-in).

3. One of the best torque to weight ratios in the market

4. Tailored end caps for double acting applications for reduced air consumption.

5. Actuators are field convertible from double acting to single acting and vice versa.

6. High visibility indicator and Double End Stops are standard, not a cost adder

7. Zero leak stop bolts achieved by carefully designed seals.

8. Hard anodised or nickel plated housing option for all aluminium body actuators.

9. Also available in carbon steel and stainless steel enclosures.

Reliable Hard anodized / nickel plated body and nickel plated steel pinion, which provides high wear and corrosion resistance, thus ensuring consistent performance over an extended operating life.

Best in class industry processes are used to manufacture these actuators which result in class leading torque/weight ratios

Designed to provide high torque with minimum space and weight. Spring package, if present, is installed inside the cylinder

Springs can be easily removed/replaced due to the use of cartridges.

2 - 10 bar (29 - 145 psig) for Rack and Pinion

2 - 7 bar (29 - 102 psig) for Scotch Yoke

Standard: -50°C to 70°C (-58°F to 158°F) with NBR Seals

High Temperature: -15°C to 160°C (5°F to 320°F) with Viton Seals

Extended Temperature - 60°C to 200°C (-76°F to 392°F) with Silicone Seals

Food safe version also available

Standard working life is 500,000 cycles according EN15714-3 (certified by TUV Nord)

Valve Shaft Interface: ISO 5211

double square, DIN 3337

VDI/VDE3845 NAMUR, EN ISO228 G1/8”, G1/4”, G1/2” based on the actuator size

VDI/VDE3845 NAMUR

Facilitates smooth engagement and operation of rack & pinion

Rugged design enabling it to be used even in demanding manual override situations offering better serviceability and precise control for modulating applications with minimal backlash.

Stem retained with steel circlip

Lubricated for life

Low weight, better strength and hard anodised / nickel plated finish.

Cartridge type, pocketed design for compactness and easy serviceability. Shot peened, oil tempered alloy steel springs with powder coated finish, enclosed in a cartridge. These cartridge type springs ensure the best fit for your valve with guaranteed fail-safe action.

An integral and de-clutchable handwheel is available as an option across all models.

Management System in Accordance with ISO 9001:2015

Valve flange: ISO 5211/DIN3337

Solenoid flange: VDE/VDI 3845 (NAMUR)

Accessory flange: VDE/VDI 3845 (NAMUR) Complies with EN60529 for IP68

European Directives: ATEX 2014/34/EU, PED and CE

1 Hard Anodised

2 Epoxy coated (200+ Hours Salt Spray Test)

3 Duraflon PTFE coating

4 FDA Compliant Epoxy Polyester Coating

5. Nickel plated

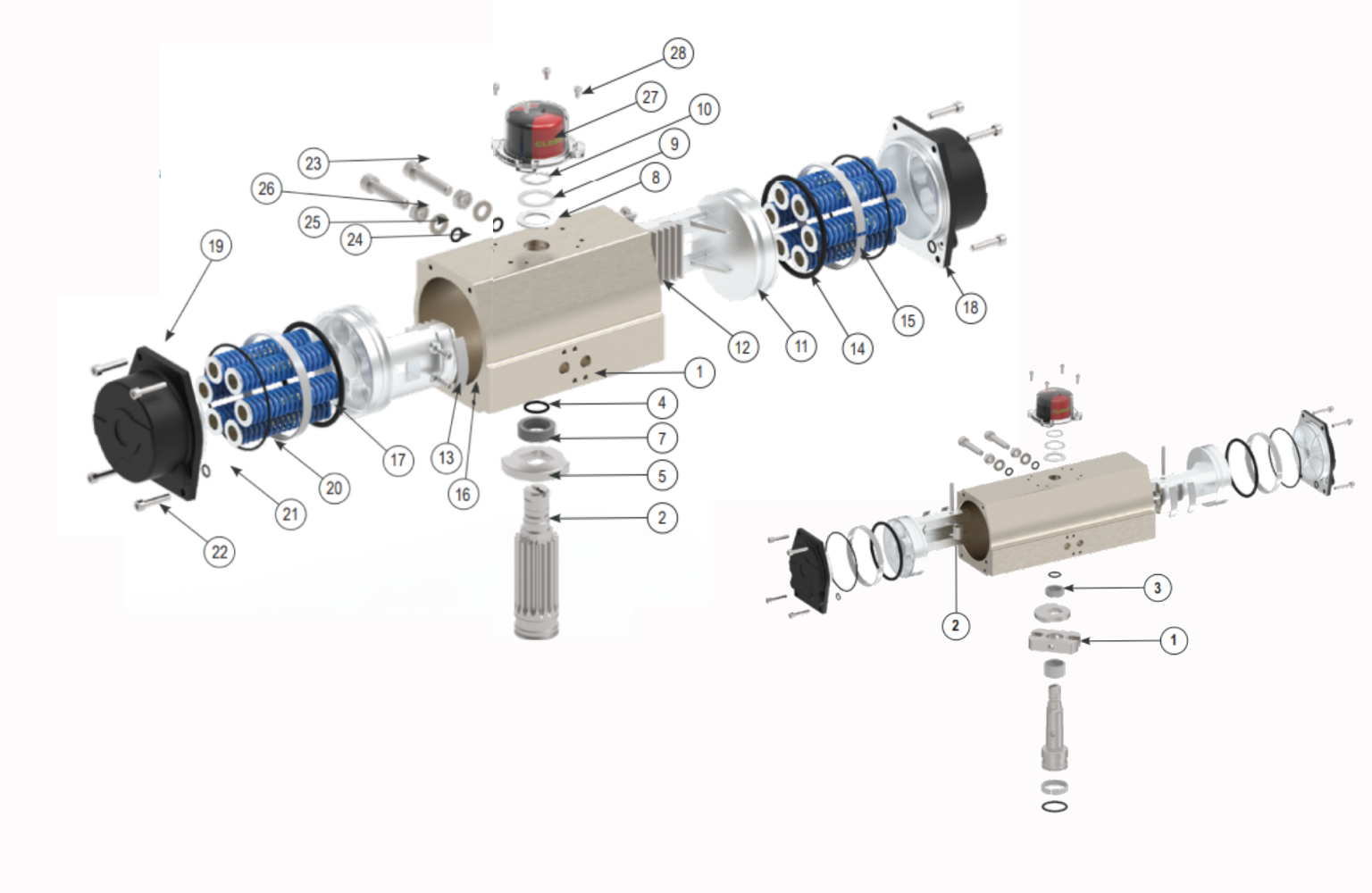

| PARTS LISTS - RACK AND PINION | ||

| ITEM | DESCRIPTION | MATERIAL |

| 1 | Housing | Aluminium |

| 2 | Pinion | Steel |

| 3 | O-Ring | Rubber |

| 4 | O-Ring | Rubber |

| 5 | Stopper | Steel |

| 6 | Wear Ring | DELRIN®/Nylon |

| 7 | Bearing Bush | DELRIN®/Nylon |

| 8 | Thrust Washer | DELRIN®/Nylon |

| 9 | Shim | Stainless Steel |

| 10 | Circlip | Stainless Steel |

| 11 | Piston | Aluminium |

| 12 | Rack | Steel |

| 13 | Socket Head Cap Screw | Stainless Steel |

| 14 | O-Ring | Rubber |

| 15 | Wear Ring | DELRIN®/Nylon |

| 16 | Wear Strip | DELRIN®/Nylon |

| 17 | Spring Cartridge | Spring Steel |

| 18 | End Cover | Aluminium |

| PARTS LISTS - RACK AND PINION | ||

| ITEM | DESCRIPTION | MATERIAL |

| 19 | End Cover | Aluminium |

| 20 | O-Ring | Rubber |

| 21 | O-Ring | Rubber |

| 22 | Socket Head Cap Screw | Stainless Steel |

| 23 | Socket Head Cap Screw | Stainless Steel |

| 24 | O-Ring | Rubber |

| 25 | Washer | Stainless Steel |

| 26 | Hex Nut | Stainless Steel |

| 27 | Indicator | Plastic |

| 28 | Socket Head Cap Screw | Stainless Steel |

| KEY PARTS - SCOTCH YOKE | ||

| ITEM | DESCRIPTION | MATERIAL |

| 1 | Yoke | Steel |

| 2 | Yoke Rollers | Steel |

| 3 | Bearing Bush | DELRIN®/Nylon/td> |